This specification is made to describe the product, product characteristics and performance, relevant measurement conditions and methods, and safety Instructions of the Cylindrical Lithium ion cell as specified in following details. The specification only applies to Tenergy Corporation.

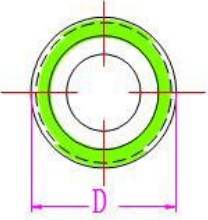

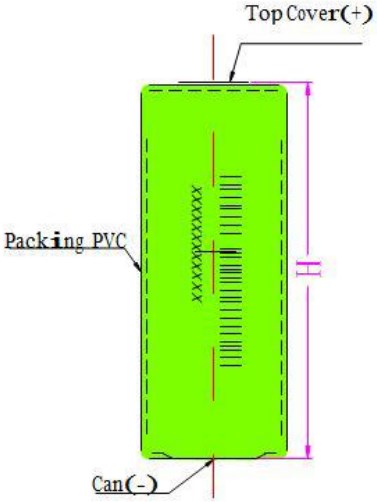

Unit: mm

Diameter (D): 14.1±0.2

Height: (H): 48.5±0.5

| No. | Items | Specifications | Remark |

| 4.1 | Capacity | Capacity | Charge the cell as item 4.7 to FC, then discharged by current 0.2C to FD. 1.0C=750mA, nC=n*750mA |

| 4.2 | Open Circuit Voltage | 3.70~3.91V | / |

| State of Charge | State of Charge | / | |

| 4.3 | Initial Internal Impedance | ≤70mΩ | / |

| 4.4 | Weight | Approx.: 19g | / |

| 4.5 | Voltage | Nominal Voltage: 3.60V | / |

| Fully Charge (FC) Voltage: 4.20V | |||

| Fully Discharge (FD) Voltage: 3.00V | |||

| 4.6 | Standard Charge Current | 0.5 C | / |

| 4.7 | Standard Charge Method | 0.5C CC (constant current) charge to FC Voltage, then CV (constant voltage) charge till charge current declines to 0.01C. | / |

| 4.8 | Charge Time | Approx 3.5 hrs. | With Standard Charge Method. |

| 4.9 | Standard Discharge Method | Using 0.2C constant current discharge to FD Voltage. | / |

| 4.10 | Max. Continuous Charge Current | 0℃~15℃:0.2C | / |

| 15℃~45℃:1.0C | / | ||

| 4.11 | Max. Continuous Discharge Current | -20℃~60℃:1.0C | / |

| 4.12 | Storage Temperature | ≤1 month: -20℃~60℃ ≤3 months: -20℃~45℃ ≤1 year: -20℃~30℃ The recoverable capacity is no less than 80% of the initial capacity. | The cell should cycle once every 3 months. Recommended storage temperature is 25±2℃ of half charge state. |

| 4.13 | Storage Humidity | 60 ±25%RH | / |

| 4.14 | Recoverable Capacity Measurement Method | Charge the cell as per Item 4.7, rest for 10 min, constant current 0.5C discharge to FD Voltage, rest for 10 min. Repeat above steps 3 times, record the maximum capacity. | / |

| 4.15 | Cosmetic Appearance | No dirt, No rupture, No leakage. | / |

| 4.16 | Standard Testing Condition | Temperature: 25±2℃ Humidity: 60 ±25%RH Atmospheric Pressure: 86-106 k Pa | / |

| No. | Items | Test Methods and Condition | Criteria |

| 5.1 | Rated Capacity | At item 4.16 condition, charge the cell as per Item 4.7, rest for 10 min, then discharge at 0.2C, 0.5C or 1C to voltage FD Voltage, record the discharge time. | 0.2C: ≥300 min 0.5C: ≥114 min 1.0C: ≥54min |

| 5.2 | Temperature Characteristics | At item 4.16 condition, charge the cell as per Item 4.7. Stored the recharged cell for 3hrs at 55 ± 2℃, 25±2℃ or -10 ± 2℃, and discharged at 0.2C to FD Voltage at the same temp., record the discharge time. | 55℃: ≥285 min 25℃: ≥300 min -10℃: ≥180 min |

| 5.3 | Cycle Life | At item 4.16 condition, constant current 0.5C charge to FC Voltage, then constant voltage FC Voltage charge to current declines to 0.01C, rest for 10 min, constant current 0.5C discharge to FD Voltage, rest for 10 min. Repeat above steps 3 times till continuously discharge capacity lower than 80% of the initial capacity of the cell. | Cycle times: ≥300 times |

| 5.4 | Store Characteristics | At item 4.16 condition, charge the cell as per Item 4.7. No outer loading circuit stores the cell 28 days, discharge at 0.2C to FD Voltage, record the discharge time. | At item 4.16 condition, charge the cell as per Item 4.7. No outer loading circuit stores the cell 28 days, discharge at 0.2C to FD Voltage, record the discharge time. |

| No. | Items | Specifications | Remark |

| 6.1 | Overcharge Test | At item 4.16 condition, charge cells with constant current 3C to voltage 4.6V, then with constant voltage 4.6V till current decline to 0.005C. Charge time no less than 8 hrs. | No fire, No explosion |

| 6.2 | Short-Circuit Test | At item 4.16 condition, charge the cell as per Item 4.7, then connect the positive and negative terminals of the cell with a circuit load having a resistance load of 80 ±20m mΩ. The temperature of the battery case is to be recorded during the test. Stop the test until the cell surface temperature has returned to ±10℃ of ambient temperature. | No fire, No explosion |

| 6.3 | Flat Crush Test | At item 4.16 condition, charge the cell as per Item 4.7. Then the cell is to be crushed between two flat surfaces. The force for the crushing is to be applied by a hydraulic ram or similar force mechanism. The flat surfaces are to be brought in contact with the cells’ wide sides and the crushing is to be continued until an applied force of 13±1kN (3000 ±224 lbs) is reached. Once the maximum force has been obtained, it is to be released, then rest for 1 hr at 25±2℃. | No fire, No explosion |

| 6.4 | Heating Test | At item 4.16 condition, charge the cell as per Item 4.7. Put the cells in the oven, the temperature of the oven is to be raised at 5±2℃ per minute to a temperature of 130±2℃ and remain for 10 minutes. | No fire, No explosion |

| 6.5 | Drop Test | At item 4.16 condition, charge the cell as per Item 4.7. Then cells or batteries were dropped from a height of 1m to a concrete surface, each cell or battery is to be dropped once in the positive and negative directions of three mutually perpendicular mounting positions for a total of 6 times, then rest for 1 hr. | No fire, No explosion |

| 6.6 | Vibration Test | At item 4.16 condition, charge the cell as per Item 4.7. Cells are firmly secured to the platform of the vibration machine without distorting the cells in such a manner as to faithfully transmit the vibration. A cell or battery is to be subjected to simple harmonic motion with the amplitude for 0.8 mm [1.6 mm total maximum excursion]. The frequency is to be varied at the rate of 1 hertz per minute between 10 and 55 hertz and return in no less than 90 no more than 100 minutes. The cell or battery is to be tested in three mutually perpendicular directions. For a cell or battery that has only two axes of symmetry, the sample is to be tested perpendicular to each axis. | No fire, No explosion |

| 6.7 | Low Pressure Test | At item 4.16 condition, charge the cell as per Item 4.7. After standard charge, store for 6h at an absolute pressure of 11.2KPa, next rest for 2hrs at 25±5℃. | No leakage, no fire, and no explosion |

The battery contains flammable materials such as organic solvents. Mishandling the battery may cause fire, smoke, or an explosion and the battery’s functionality will be seriously damaged. Protection circuitry must be designed into the application device to protect the battery. Additionally, Tenergy Corporation highly recommends adding these instructions to the owner’s manual. Please read and check the following prohibited actions.

The battery shall be with the overcharge protection, over-discharge protection, and over-current protection during using. Protective circuit must have protective functions as follows:

The cell shall be discharged at less than the maximum discharge current specified in the Specification Approval Sheet. A high discharge current may reduce the discharge capacity observably or cause overheating.